FORMOPAK 2400 K

PURPOSE OF THE MACHINE

FORMOPAK 2400 K is an automatic machine intended for measuring, dosing and closing of small PVC and polystyrene containers, with the simultaneous production of this packaging on the machine itself, by the thermoforming process.

The machine is delivered for small packaging of tea in PVC teaspoons that are formed on the machine itself and come out of the machine as a package with four teaspoons.

Closing is done by thermal welding using a constantly heated iron. It is easy to handle, so it can be operated by workers with a lower level of competence.

TECHNICAL DESCRIPTION

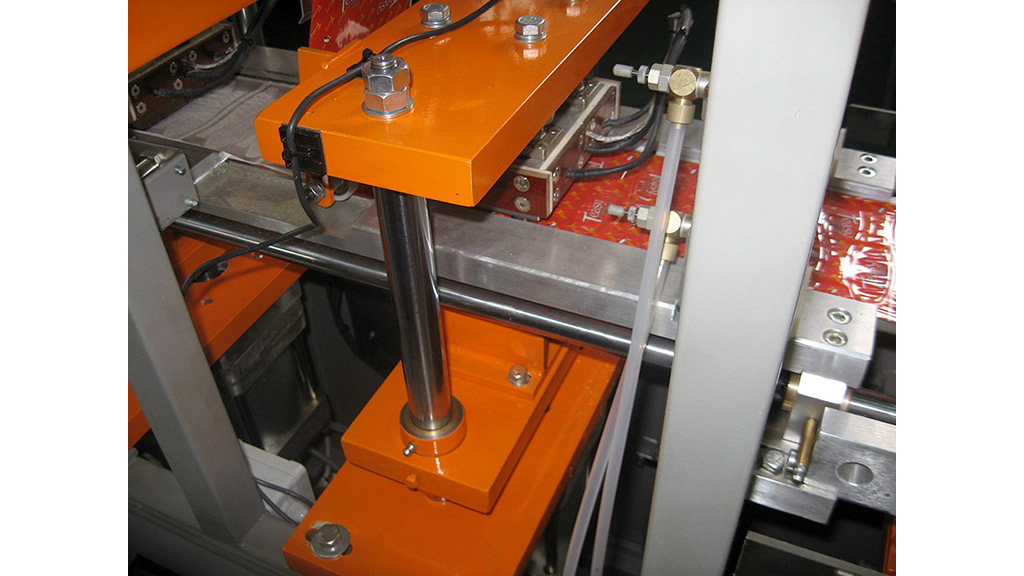

According to the mode of operation and control characteristics, this is a two-row line machine, horizontal, with a tact mode of operation. It consists of several units – modules, integrated into one functional unit, whose operation is controlled by a programmable logic controller (PLC).

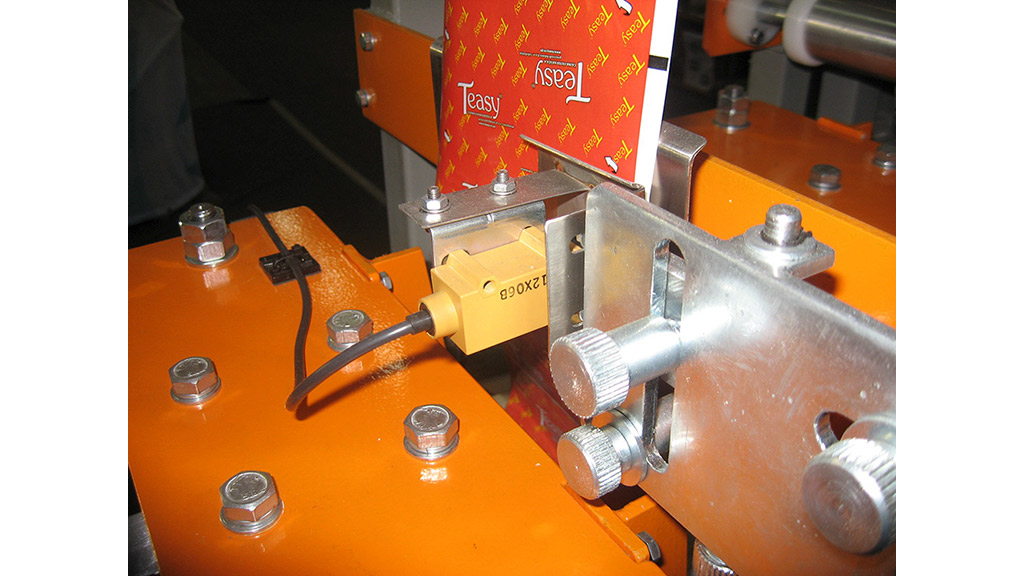

According to the type of drive, this machine is a combination of pneumatic and mechanical mechanisms, which also perform the functions of forming containers, measuring and dosing mass, closing containers with felt, closing containers with polyethylene, cutting, removing from the machine and winding of waste foil.

This machine is equipped with a bucket dosing mechanism for various types and shapes of teas. The containers are closed by welding the filter paper, and then by welding the polyethylene foil. After welding, the strip is cut off, the filled containers fall on the conveyor that takes them out of the machine, and the waste is wound on the receiving sleeve. The temperature of the iron is controlled by a thermoregulator.

All elements that come into contact with the material to be packaged are made of stainless steel and other materials certified for use in the food industry. For proper operation of the device, it is necessary to be serve by two operators. The first operator manages the process of the machine, while the second operator works on bringing the packaging and taking the finished products to the warehouse.

TECHNICAL CHARACTERISTICS

| – machine capacity | Q = 2400 units / h |

| – dosing range | 4 x 10 grams |

| – installed power | Pi = 3 kW |

| – nominal voltage | U = 3 x 380 V 50 Hz |

| – nominal pressure | P = 6 – 8 bar |

| – air consumption (at 6 bar) | 480 Nl / min |

| – machine dimensions L x W x H | 3500 x 900 x 2000 mm |

| – machine weight | M = 1350 Kg |