MONOPAK 1000 – 4500 20 P T clean

PURPOSE OF THE MACHINE

MONOPAK 1000 – 4500 20P T clean is intended for filling containers with sour milk products, and with the possibility of implementing various types of dispensers for liquid, pasty, creamy, piece, powder or granular substances used in various industries.

On this machine can pack containers in several sizes and dimensions with a maximum volume of up to 2 liters (kilograms), with the necessary adjustment of certain parameters.

TECHNICAL DESCRIPTION

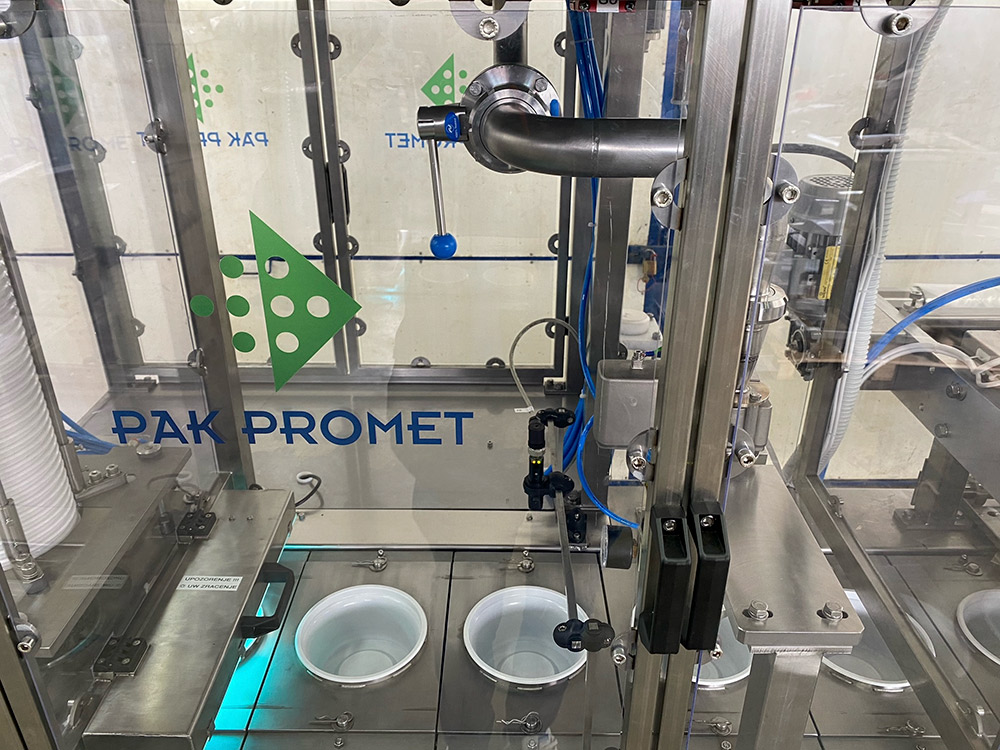

This single-row (three-row), linear horizontal machine works in the tact mode, and according to the type of drive and mode of operation is a combination of mechanical and pneumatic mechanisms – modules.

The role of interphase connection of all elements of the machine cycle is performed by the conveyor, which transfers the cups from one mechanism to another, all the way to the cup ejector which takes them to the receiving table from where the worker collects them and packs them collectively.

The machine is made for filling into containers according to the sample. Dosing is with KROHNE flowmeters and FESTO sphincters, which enables filling with pieces of fruit up to 8 mm, and the dispenser is powered from the container located on the machine

Filled containers are transported to the PP foil closure assembly. The foil is rewound by means of an electric motor, the assembly is equipped with a waste winding system. Slicing PP film is done with specially profiled knives that are adapted to the format and shape of the container

The machine is equipped with a control unit with a touch panel for easier control of the parameters of the exploitation process.

CIP washing is fully automated. The base of the machine, protective linings, and other elements that come into contact with the material to be packaged are made of stainless steel.

The machine comes with a traverse and ink-jet printer.

TECHNICAL CHARACTERISTICS

| – machine capacity | Q = 1000 – 4500 container / h for filling up to 1000 grams |

| – dosing range | 0,50 – 2,00 kg |

| – installed power | Pi = 3,50 kW |

| – nominal voltage | 3 x 380 V 50 Hz |

| – nominal pressure | P = 6 – 8 bar |

| – air consumption (at 6 bar) | 200 – 250 L / min |

| – machine dimensions L x W x H | 4300 x 1300 (1950) x 2850 mm |

| – machine weight | M = 1.700 – 2.000 Kg |